Manufacturing Process

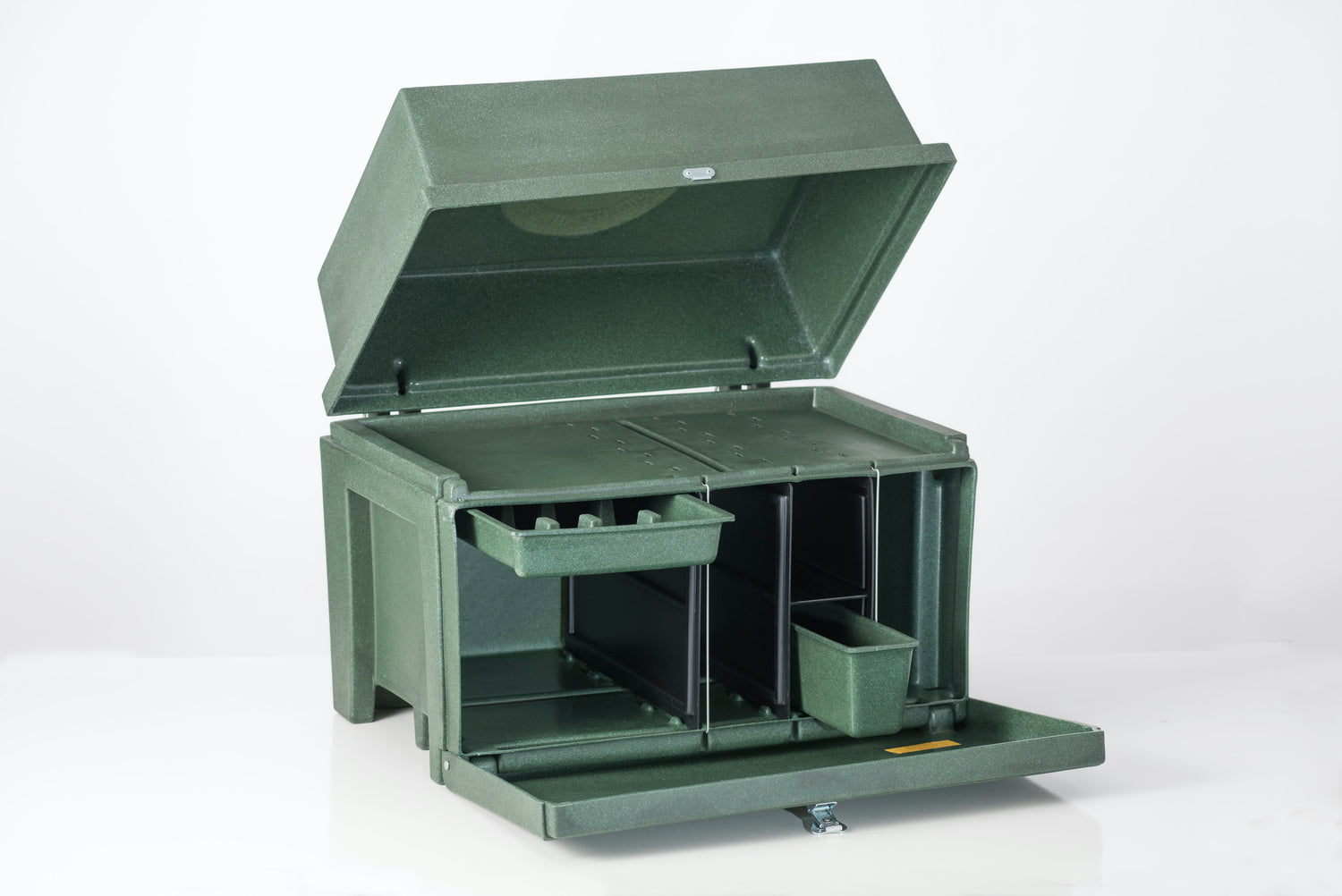

We build the Chuck Box Camp Kitchen to last, but a product’s toughness and durability can be difficult to see in a flat photo on a website. People have asked us if the Chuck Box Camp Kitchen will hold up during constant off-roading and the answer is yes, it will.

Since it is made in the USA and we oversee the production process, we stand by the toughness and durability of the Chuck Box Camp Kitchen.

Here’s how we build our camp kitchens to last:

1. It’s starts with a polymer powder in a color we call “Chuck Box Green.” The polymer is poured into the Chuck Box Camp Kitchen molds.

2. Next, the polymer-filled molds are heated and rotated in a high-temperature oven until all the polymers are melted and have adhered to the walls of the mold. Rotational-molding or roto-molding creates a seamless finished product, making it exceptionally durable. It allows for features like molded handles that will never break off or get caught on other equipment.

3. After the heating process comes the cooling process. This is a lengthy process whereby it has to cool to the point where it can be safely handled by a human operator.

4. After the raw pieces are molded and cooled, the team hand shapes the interior. It’s labor and time intensive, but the highly-skilled men and women who hand-shape the Chuck Box Camp Kitchen take pride in every piece they make.

The final product is a USA made camp kitchen (see below for a video of how it is made).